Here is my "mini-mill" project, which I am building as precursor to a more ambitious unit. I have been studying historical sources and examining modern horizontal mills to get guidance and inspiration.

The shoe and damsel meters out the flow of grain into the eye of the runner stone. It was fun to build this part and it works great.

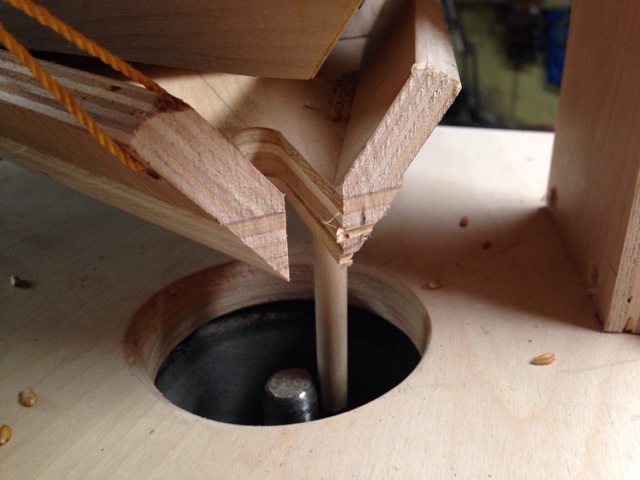

Here you can see the runner stone and the octagonal housing I built. I glued a little flag onto the outside of the runner stone to help create some wind to push the flour out. You can also see that I ground the top of the spindle to create an eccentric that the damsel rides against. This jostles the shoe and helps the grain flow out evenly.

The pattern is a classic layout of lands and furrows. Grain enters from the top and moves out as it is reduced into flour or feed.

Here is an early fit up, trying to figure out how the housing is going to work. The bed stone is bolted down to the base, and the spindle is supported on a bearing mounted on the bridge tree below. The crane, screw, and bale (at right) can then be rotated to raise and lower the spindle.

This is the bedstone after removing from the form, with the top bearing I used. This top bearing seems to bind on the spindle and prevent it from moving up and down smoothly. I am going to try a hardwood top bearing next. Hardwood top bearings have been used in stone mills for centuries.

I cut the form to make the furrows and lands as a three-dimensional mirror image using a dado head on a radial arm saw, then dropped it into the bottom of a 12" diameter bucket and put in counter top mix cement.

No comments:

Post a Comment