I purchased 6 bushels of compromised red fife spring wheat that I hope will be viable for a planting in 2016. The wheat measured 19% humidity when I bought it last Sunday. Ouch! The smell was obvious without any need of testing, and I was pretty amazed that it was not actively sprouting or getting black inside.

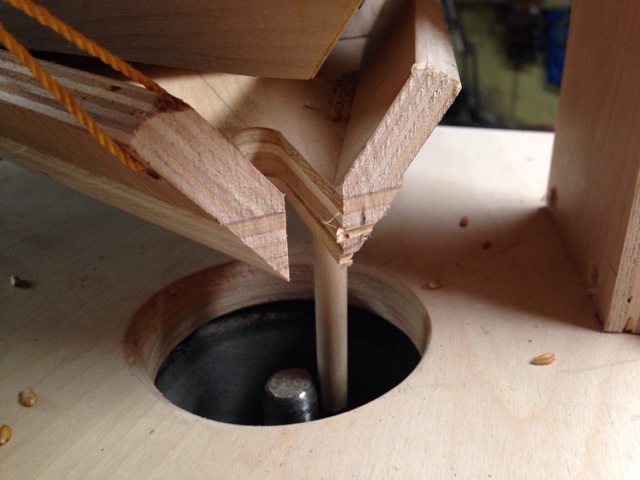

Anyway, I needed to build a dryer ASAP. Turns out 55 gallons is almost exactly 6 bushes, so I grabbed this barrel and cut off the top. On the bottom I built a wooden box with a small blower. On top of the wooden box I cut 3" holes and stapled window screen over the openings.

So here you can see the setup. After a couple of days I added the ceramic heater, so the blower draws in some hot air. You can really feel the air moving through the grain and coming out the top. For the first couple of days, the moisture level hardly moved. But 2 full days of heat really got it going, and today it is testing in the 13's. The volume has gone down noticeably--the pile of grain is about 3" lower now! I will give it another day or two before bagging and storing, and doing a good germination test on the lot.

I'm really glad I took the time to build a gate to draw grain off the bottom. I have been draining a couple of buckets each day and pouring it back on top, to agitate and move the grain around. It should make bagging very easy, too.